Product Description

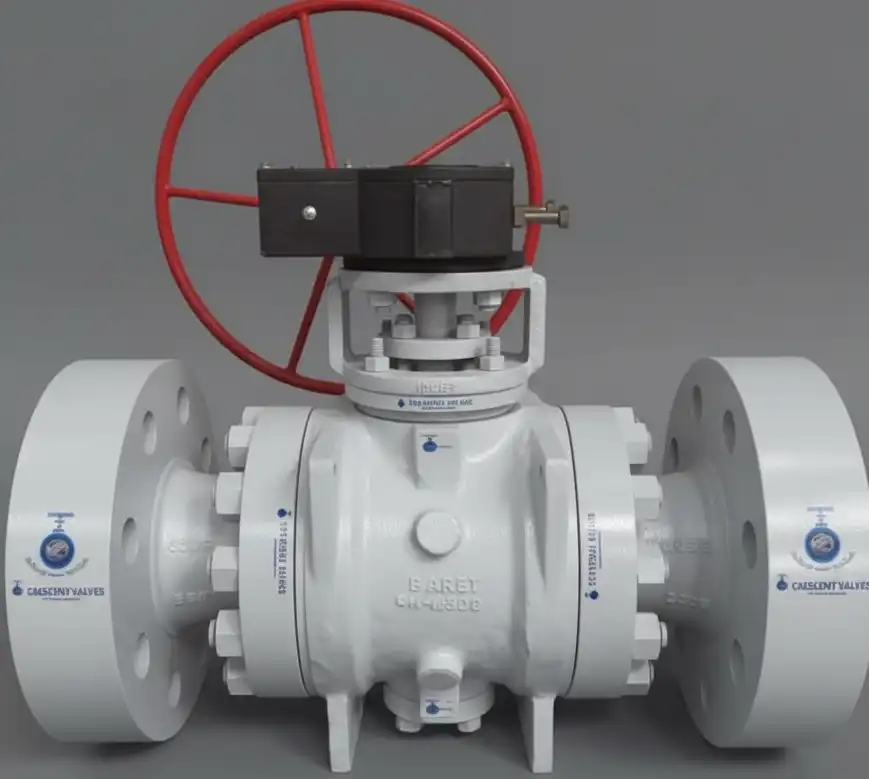

Crescent Valves manufactures a comprehensive range of Trunnion Mounted Ball Valves in sizes from 2″ to 40″ (DN 50 to DN 1000) and pressure ratings from Class 150# to 2500#, designed to deliver reliable flow control and tight shut-off in a wide range of process applications.

These valves are available in various combinations of sizes, pressure classes, materials of construction, and end connections to meet the specific requirements of industries such as oil & gas, petrochemical, chemical, and power plants.

Crescent Trunnion Mounted Ball Valves are offered in both full-bore and reduced-bore designs, providing flexibility for different flow and process conditions. The trunnion-mounted design reduces operating torque, ensures enhanced durability, and maintains tight sealing under high-pressure and high-temperature conditions.

Crescent Trunnion Mounted Ball Valves are engineered to provide optimal performance, durability, and safety in demanding industrial processes

Specification

- Size: 2″ to 40″ (DN 50 to DN 1000)

- Rating: ASME CL 150 to 2500

- Design: ASME B 16.34 / ISO 17292 / API 608 / API 6D

- Face to Face: ASME B 16.10

- End Connection: ASME B 16.5 / ASME B 16.25

- Testing: API 598 / API 6D / ISO 5208 / BS EN 12266-1

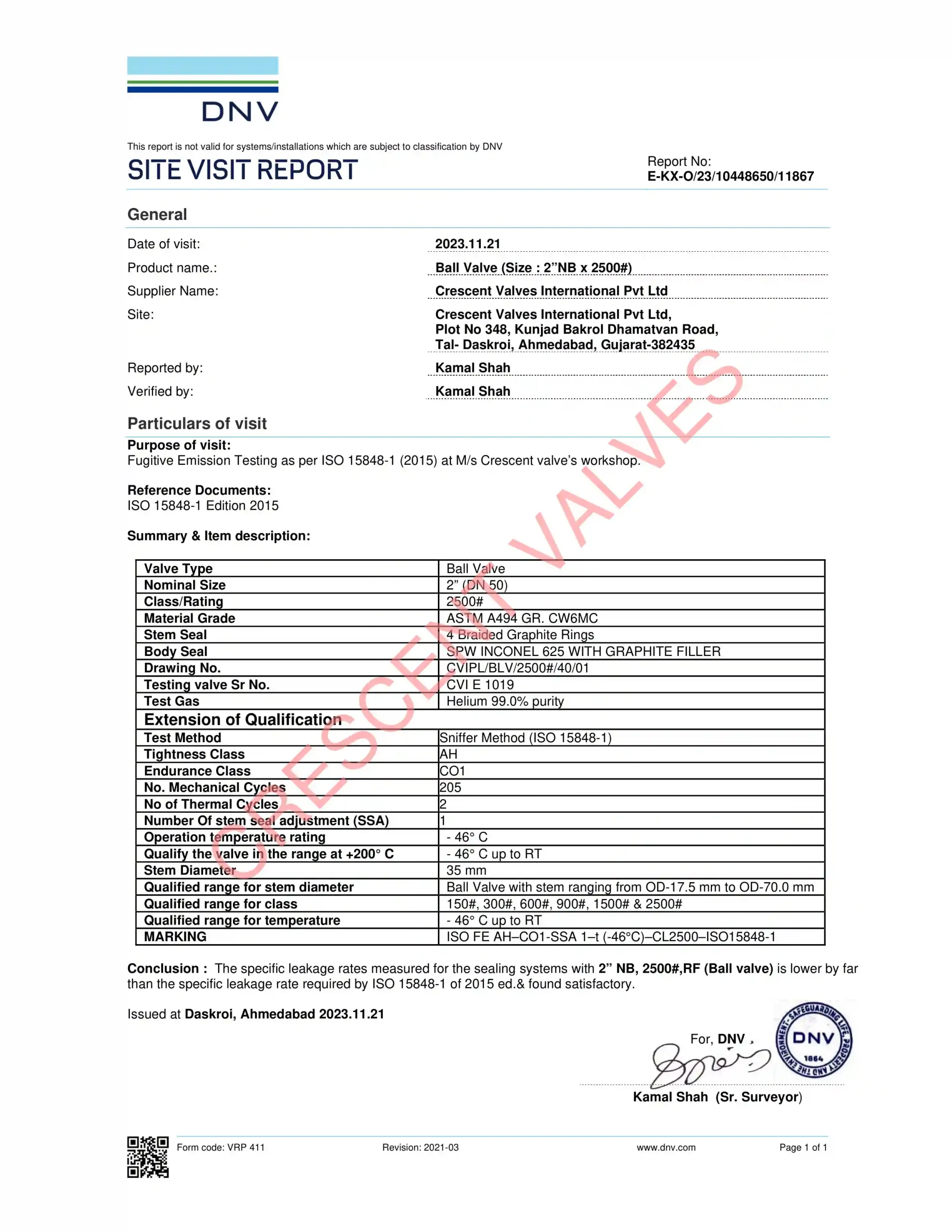

- Fugitive Emission: ISO 15848 Part 1 & 2 / MESC SPE 77/312

- Fire Safe: API 607 / API 6FA

- Special: NACE MR 0175

- Material: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconnel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Features

- Double block and bleed (DBB) feature – Valves are designed and tested for automatic cavity relief

- Fire Safe Design

- Blowout-proof stem

- High integrity stem sealing

- Mirror-finished solid ball

- Antistatic feature

- Low Emission

- Soft & Metal Seated

- Where tight shut off is required, Double piston effect (DPE) seats provided for redundancy in sealing

- Extended Bonnet for Cryogenic Services

- Actuator-mounting flange conforms to ISO 5211

- Variety of actuation options

Technical Data

| PART NAME | DESCRIPTION |

|---|---|

| Body | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| Side PC / Adapter | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800 / Alloy 20 / Titanium |

| Ball | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze / Alloy 20 / Titanium |

| Seat Insert | PTFE / R-PTFE / PEEK / NYLON / DEVLON / DELRIN |

| Seat Ring | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Seat Spring | Inconel X-750 / 718 |

| Stem | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| O Ring | Viton / HNBR |

| Trunnion Cover | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| Trunnion | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze / Alloy 20 / Titanium |

| Bolting | A193 B7 / A320 L7 / A193 B8/ Alloy / Inconel 925 |

| Bolting | A194 2H / A194 8 / Alloy / Inconel 925 |

* For more details download our Catalogue and any other material contact the factory

Product Description

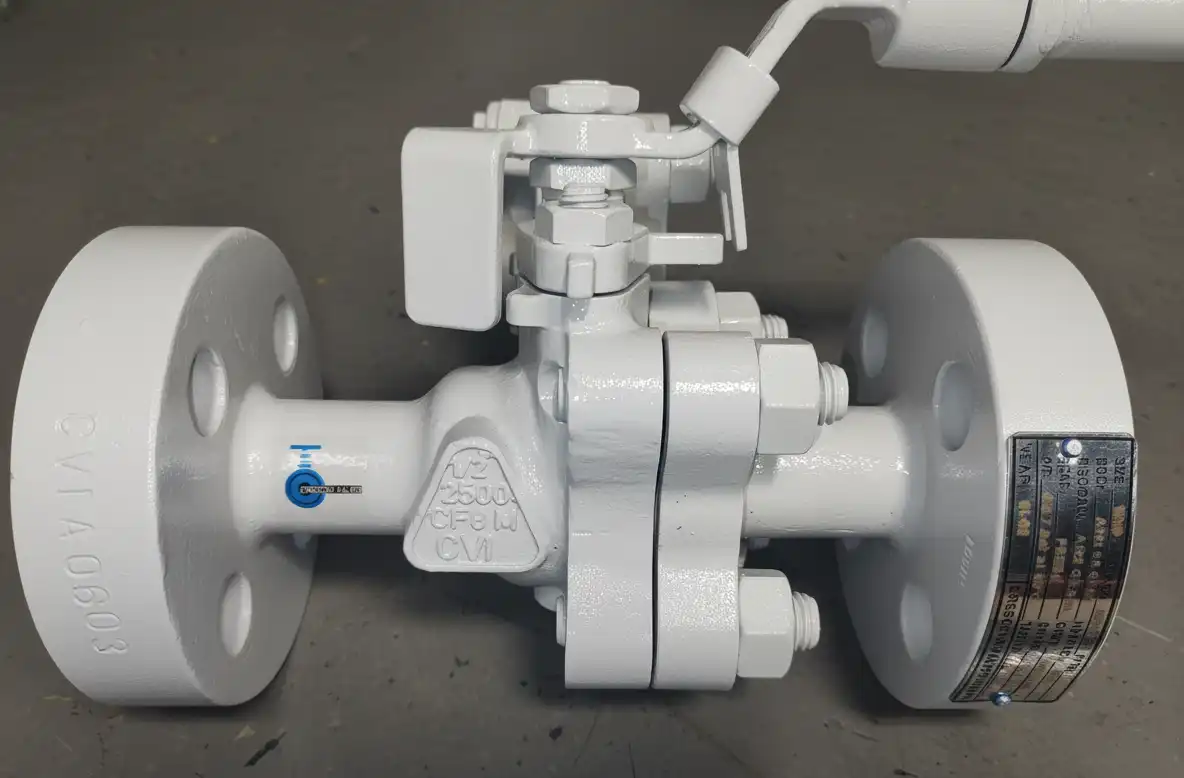

Crescent Valves manufactures a comprehensive range of Floating Type Ball Valves in sizes up to 8″ (DN 200) and pressure ratings from Class 150# to 2500#, designed for reliable flow control and tight shut-off in various process industries.

These valves are available in multiple combinations of sizes, pressure classes, materials of construction, and end connections to meet the specific requirements of chemical, petrochemical, oil & gas, and power plant applications.

The floating-ball design allows the ball to move slightly towards the downstream seat under line pressure, ensuring bubble-tight sealing and consistent performance. Crescent Floating Ball Valves are offered in both full-bore and reduced-bore configurations, with a wide selection of materials and end connections to suit customer-specific process requirements.

Crescent Floating Ball Valves combine durability, ease of operation, and reliable sealing performance, making them ideal for a broad range of industrial processes

Specification

- Size: 1/2″ to 8″ (DN 15 to DN 200)

- Rating: ASME CL 150 to 2500

- Design: ASME B 16.34 / ISO 17292 / API 608 / API 6D

- Face to Face: ASME B 16.10

- End Connection: ASME B 16.5 / ASME B 16.25 / ASME B16.11 / ASME B 1.20.1

- Testing: API 598 / API 6D / ISO 5208 / BS EN 12266-1

- Fugitive Emission: ISO 15848 Part 1 & 2 / MESC SPE 77/312

- Fire Safe: API 607 / API 6FA

- Special: NACE MR 0175

- Material: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconnel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Features

- Fire Safe Design

- Blowout-proof stem

- High integrity stem sealing

- Mirror-finished solid ball

- Antistatic feature

- Low Emission

- Soft & Metal Seated

- Extended Bonnet for Cryogenic Services

- Actuator-mounting flange conforms to ISO 5211

- Variety of actuation options

Technical Data

| PART NAME | DESCRIPTION |

|---|---|

| Body | ASTM A105 / ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| Side PC / Adapter | ASTM A105 / ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| Ball | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze / Alloy 20 / Titanium |

| Seat Insert | PTFE / R-PTFE / PEEK / NYLON / DEVLON / DELRIN |

| Seat Ring | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Stem | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Bolting | A193 B7 / A320 L7 / A193 B8/ Alloy / Inconel 925 |

| Bolting | A194 2H / A194 8 / Alloy / Inconel 925 |

* For more details download our Catalogue and any other material contact the factory