Product Description

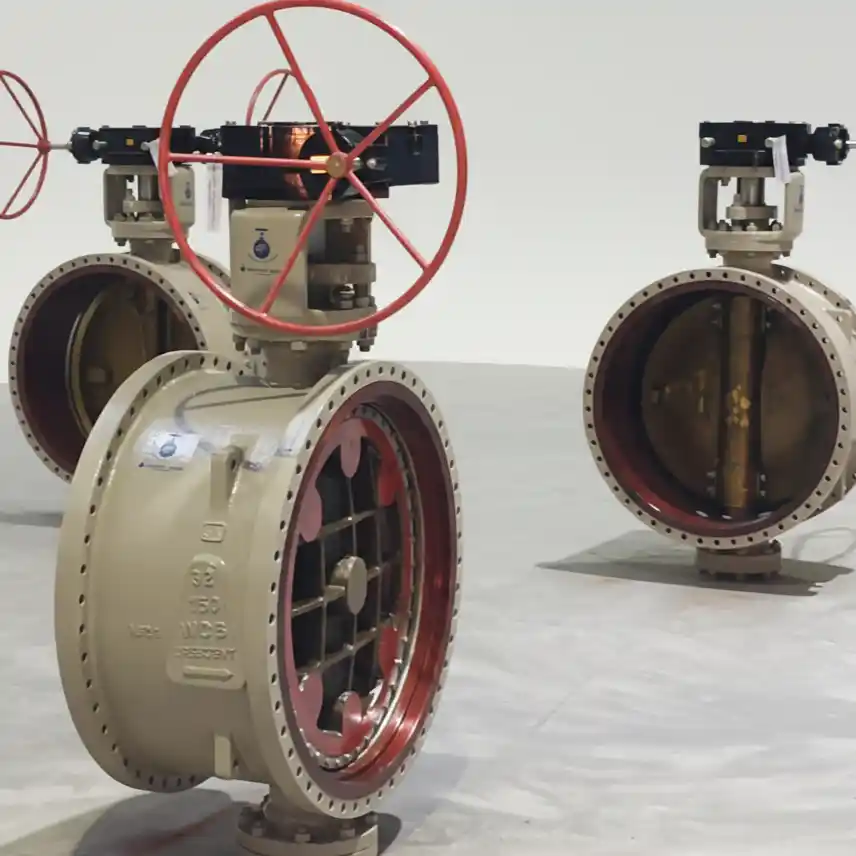

Crescent Valves manufactures a comprehensive range of Butterfly Valves in sizes from 2″ to 60″ (DN 50 to DN 1500) and Pressure Rating from 150# to 300#, engineered to deliver reliable flow control and shut-off performance in a wide range of industrial applications.

These valves are available in various combinations of size, pressure class, materials of construction, seating options, and end connections to meet the specific requirements of different process plants and operating conditions.

Crescent Butterfly Valves are offered in Centric (Concentric), Double Offset, and Triple Offset configurations to suit varied service conditions:

- Centric (Concentric) Design: Features a resilient soft seat and is ideal for general-purpose applications, providing bubble-tight sealing and easy operation in low-pressure systems.

- Double Offset Design: Incorporates a slightly eccentric shaft and disc arrangement, minimizing friction between the disc and seat, enhancing durability, and allowing operation in higher pressure and temperature services.

- Triple Offset Design: Employs a metal-to-metal sealing system with triple eccentricity for critical and severe service conditions, ensuring zero leakage, extended service life, and suitability for high-temperature, high-pressure, and corrosive applications.

The valves are available with Soft Seats (EPDM, NBR, PTFE, DEVLON) and Metal Seated options, including Extended Stem designs for insulated or underground piping systems.

Specification

- Type: Concentric, Double offset and Tripple Offset

- Size: 2″ to 60″ (DN 50 to DN 1500)

- Rating: ASME CL 150 to 300

- Design: API 609, BS EN 55353 , AWWA C504

- Face to Face: API 609, ISO 5752

- End Connection: Wafer, Lugged, Double Flanged (Shot Pattern & Long Pattern)

- Testing: API 598 / ISO 5208

- Fugitive Emission: ISO 15848 Part 1 & 2

- Fire Safe: API 607 / API 6FA

- Special: NACE MR 0175

- Material: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconnel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Features

- Fire Safe Design

- Blowout-proof stem

- High integrity stem sealing

- Metal Seat Suitable for High Temp. with leakage rate of class IV

- Bubble Tight Shut off

- Antistatic feature

- Low Emission stem sealing

- Extended bonnet for low temperature and Cryogenic applicaitons

- Actuator-mounting flange conforms to ISO 5211

- Variety of actuation options

Technical Data

| PART NAME | DESCRIPTION |

|---|---|

| BODY | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| DISC | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| RETAINER | ASTM A105 / SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| STEM | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| SEAT | PTFE / RPTFE / DEVLON / METAL TO METAL SEAT |

| Bolting | A193 B7 / A320 L7 / A193 B8/ Alloy / Inconel 925 |

| Bolting | A194 2H / A194 8 / Alloy / Inconel 925 |

* For more details download our Catalogue and any other material contact the factory