Product Description

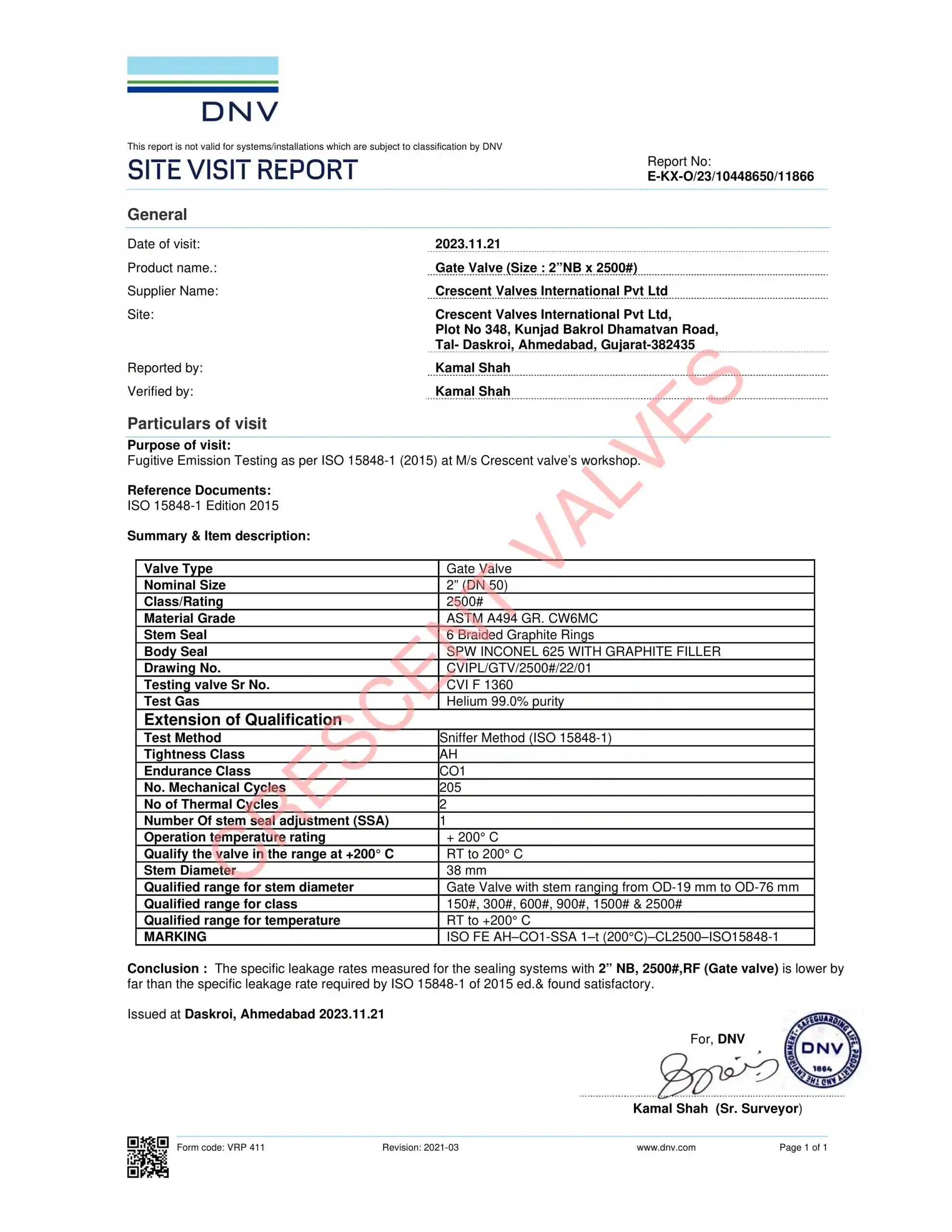

Crescent Valves manufactures a comprehensive range of Cast Steel Gate Valves in sizes from 2″ to 40″ (DN 50 to DN 1000) and pressure ratings from 150# to 2500#, designed to provide reliable isolation and flow control in a wide range of industrial applications

These valves are available in multiple combinations of sizes, pressure classes, materials of construction, and end connections to meet the requirements of oil & gas, petrochemical, chemical, and power plant industries.

Crescent Gate Valves are offered in both Bolted Bonnet and Pressure Seal designs, with options for flexible or solid wedge configurations, ensuring tight shut-off and long-term durability. A wide selection of materials and end connections allows these valves to perform reliably under diverse service conditions, including high-pressure, high-temperature, and corrosive environments.

Crescent Cast Steel Gate Valves combine robust construction, reliable performance, and ease of operation, making them ideal for critical industrial process applications.

Specification

- Size: 2″ to 40″ (DN 50 to DN 1000)

- Rating: ASME CL 150 to 2500

- Design: ASME B 16.34 / ISO 17292 / API 602 / API 600

- Face to Face: ASME B 16.10

- End Connection: ASME B 16.5 / ASME B 16.25

- Testing: API 598 / BS EN 12266-1

- Fugitive Emission: ISO 15848 Part 1 & 2 / API 624

- Fire Safe: API 607 / API 6FA

- Special: NACE MR 0175

- Material: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconnel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Features

- Fire Safe Design

- OS & Y, Rising Stem

- Bolted Bonnet & Pressure Seal Design

- Extended Bonnet for Cryogenic Services

- Bypass On Request

- Locking Device Request

- Actuator-mounting flange conforms to ISO 5211

- Variety of actuation options

Technical Data

| PART NAME | DESCRIPTION |

|---|---|

| Body | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800 / Titanium |

| BONNET | ASTM A 494 CW6MC / ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800 / Titanium |

| WEDGE | ASTM A 494 CW6MC / ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800 / Titanium |

| STEM | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| SEAT RING | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Bolting | A193 B7 / A320 L7 / A193 B8/ Alloy / Inconel 925 |

| Bolting | A194 2H / A194 8 / Alloy / Inconel 925 |

* For more details download our Catalogue and any other material contact the factory

Product Description

Crescent Valves manufactures a comprehensive range of Forged Steel Gate Valves in sizes from ½” to 2″ (DN 15 to DN 50) and pressure ratings from 150# to 2500#, designed to provide reliable isolation and flow control in high-pressure process applications.

These valves are available in multiple combinations of size, pressure class, materials of construction, and end connections to meet the requirements of chemical, petrochemical, oil & gas, and power plant applications.

Crescent Forged Steel Gate Valves feature a solid wedge design, ensuring tight shut-off and long-term durability. They are offered in both Bolted Bonnet and Welded Bonnet configurations, providing versatility for various process and service conditions. A wide selection of materials and end connections ensures these valves deliver reliable performance, resistance to wear and corrosion, and suitability for high-pressure service.

Crescent Forged Steel Gate Valves combine robust construction, durability, and reliable operation, making them ideal for critical process applications.

Specification

- Size: 1/2″ to 2″ (DN 15 to DN 50)

- Rating: ASME CL 150 to 2500

- Design: API 602 /BS 5352 / ASME B 16.34

- Face to Face: As per Mfg (SW/THD) / ASME B 16.10 (Flange)

- End Connection: ASME B 16.11 / ASME B 2.1 / ASME B16.5

- Testing: API 598 / BS EN 12266-1

- Fugitive Emission: ISO 15848 Part 1 & 2 / API 624

- Fire Safe: API 607 / API 6FA

- Special: NACE MR 0175

- Material: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconnel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Features

- Fire Safe Design

- OS & Y, Rising Stem

- Bolted Bonnet & Welded Bonnet

- Extended Bonnet for Cryogenic Services

- Pup Piece extension on ends

- Locking Device Request

- Actuator-mounting flange conforms to ISO 5211

- Variety of actuation options

Technical Data

| PART NAME | DESCRIPTION |

|---|---|

| Body | ASTM A105 / SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| BONNET | ASTM A105 / SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| WEDGE | ASTM A105 / SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| STEM | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| SEAT RING | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Bolting | A193 B7 / A320 L7 / A193 B8/ Alloy / Inconel 925 |

* For more details download our Catalogue and any other material contact the factory