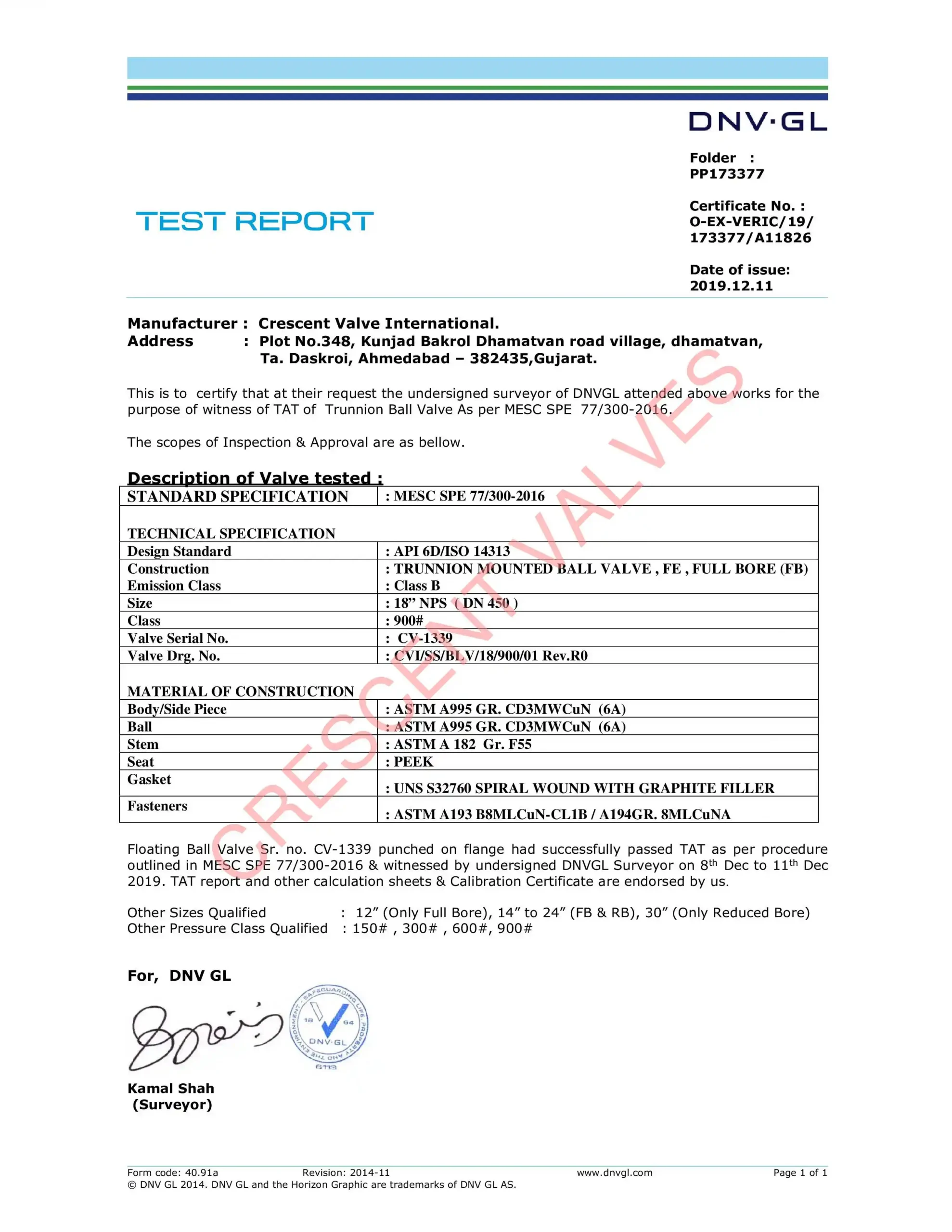

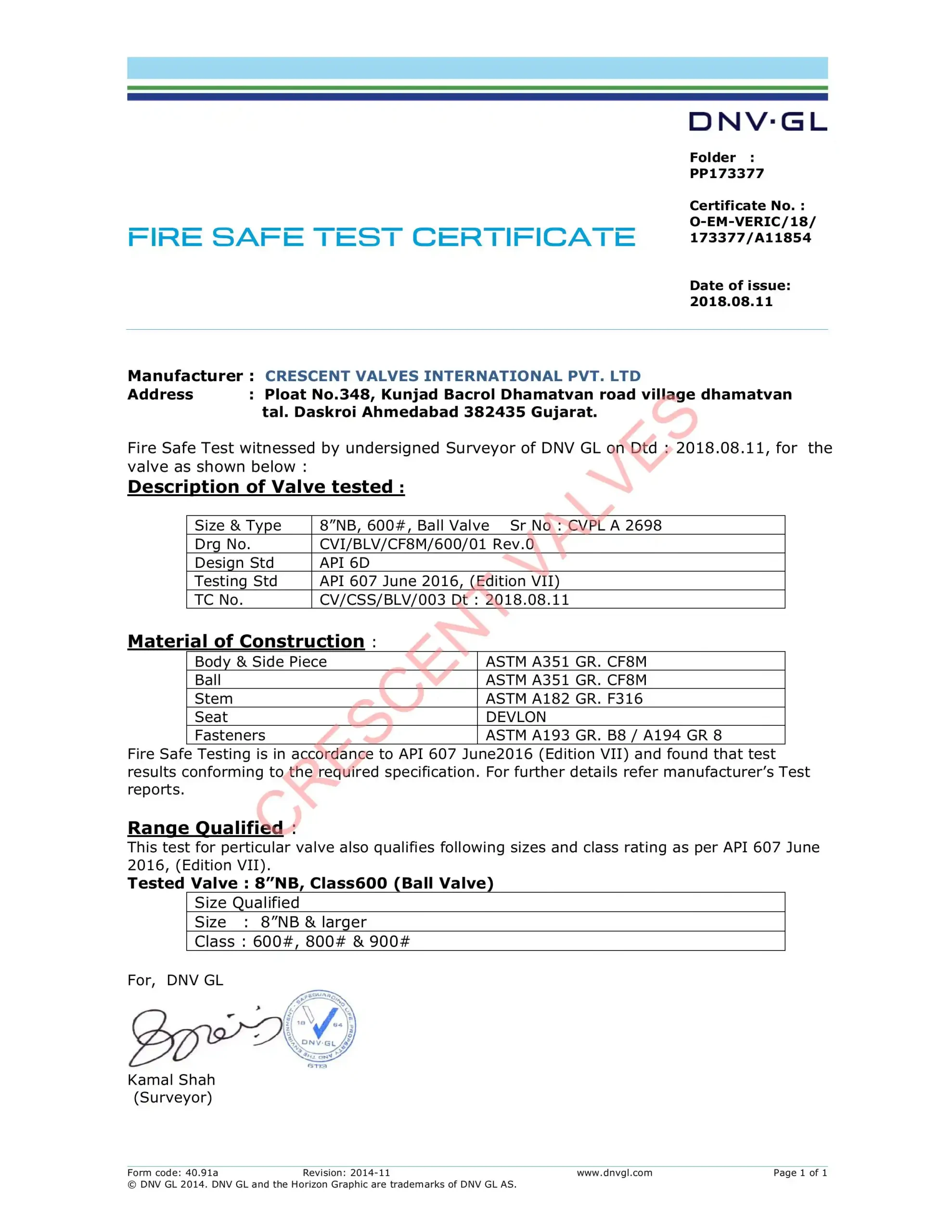

Product Description

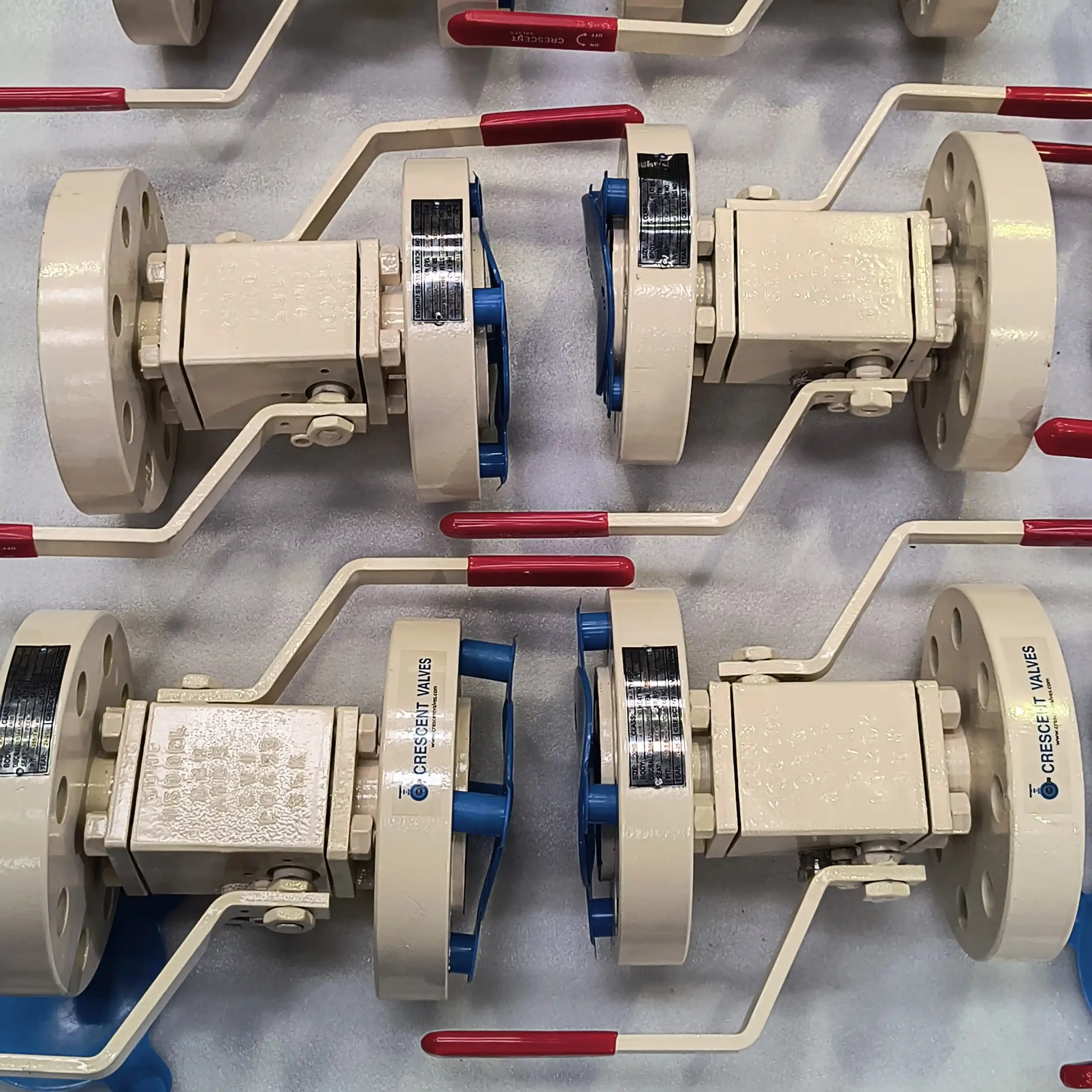

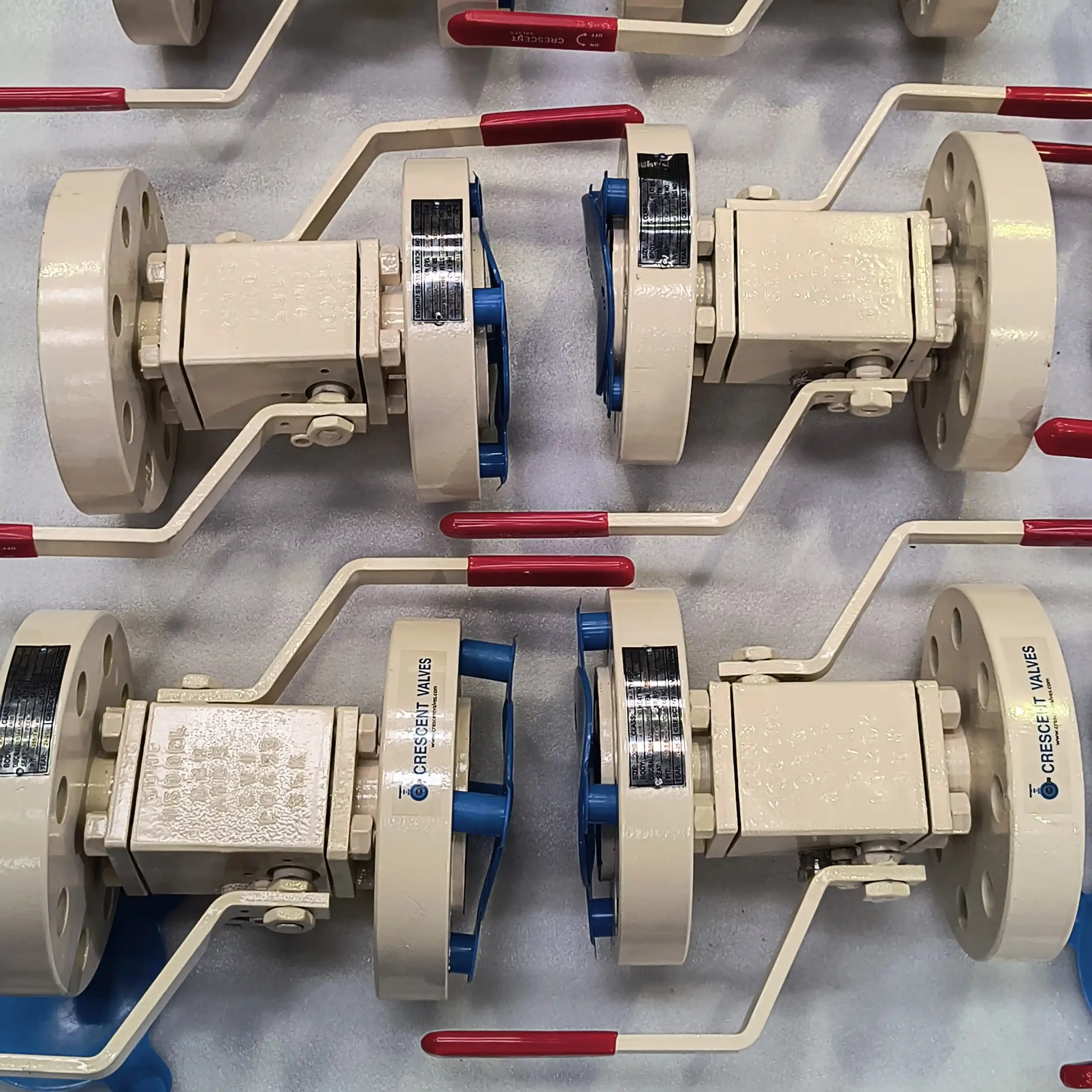

Crescent Valves manufactures a comprehensive range of Double Block and Bleed (DBB) Trunnion Design Ball Valves in sizes from 6” to 24” (DN 150 to DN 600) and pressure Rating from 150# to 2500#, designed to provide positive isolation and safe venting in critical process applications.

These valves are offered in various combinations of size, pressure class, materials of construction, and end connections to meet the demanding requirements of oil & gas, petrochemical, refinery, and pipeline applications.

Crescent DBB Trunnion-Mounted Ball Valves are particularly suitable for upstream and high-pressure applications, or services involving coarser, unrefined media. The trunnion-mounted design offers enhanced strength, lower operating torque, and improved sealing performance.

The valves incorporate spring-energized seats that ensure tight sealing even under low differential pressure conditions. The Double Block and Bleed configuration provides two independent seating surfaces that isolate the process fluid from both sides, while the bleed port allows safe cavity venting or pressure monitoring.

DBB Valves are available in Ball–Needle–Ball configurations with options for soft-seated or metal-to-metal sealing to suit diverse service conditions. The bonnet-to-body connection is engineered for superior, bubble-tight sealing even at elevated pressures and temperatures, ensuring operational reliability and safety.

Specification

- Size: 6” to 24” (DN 150 to DN 600)

- Rating: ASME CL 150 to 2500

- Design: ASME B 16.34 / ISO 17292 / API 608 / API 6D

- Face to Face: As per Mfg.

- End Connection: ASME B 16.5 / ASME B 16.25 / ASME B16.11 / ASME B 1.20.1

- Testing: API 598 / API 6D / ISO 5208

- Fugitive Emission: ISO 15848 Part 1 & 2 / MESC SPE 77/312

- Fire Safe: API 607 / API 6FA

- Special: NACE MR 0175

- Material: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconnel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Features

- Compact Design

- Fire Safe Design

- Blowout-proof stem

- High integrity stem sealing

- Mirror-finished solid ball

- Antistatic feature

- Low Emission

- Soft & Metal Seated

- Extended Stem Desgin for Cryogenic Service

- Actuator-mounting flange conforms to ISO 5211

- Variety of actuation options

Technical Data

| PART NAME | DESCRIPTION |

|---|---|

| Body | ASTM A105 / ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| Side PC / Adapter | ASTM A105 / ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| Ball | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze / Alloy 20 / Titanium |

| Seat Insert | PTFE / R-PTFE / PEEK / NYLON / DEVLON / DELRIN |

| Seat Ring | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Stem | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Bolting | A193 B7 / A320 L7 / A193 B8/ Alloy / Inconel 925 |

| Bolting | A194 2H / A194 8 / Alloy / Inconel 925 |

* For more details download our Catalogue and any other material contact the factory

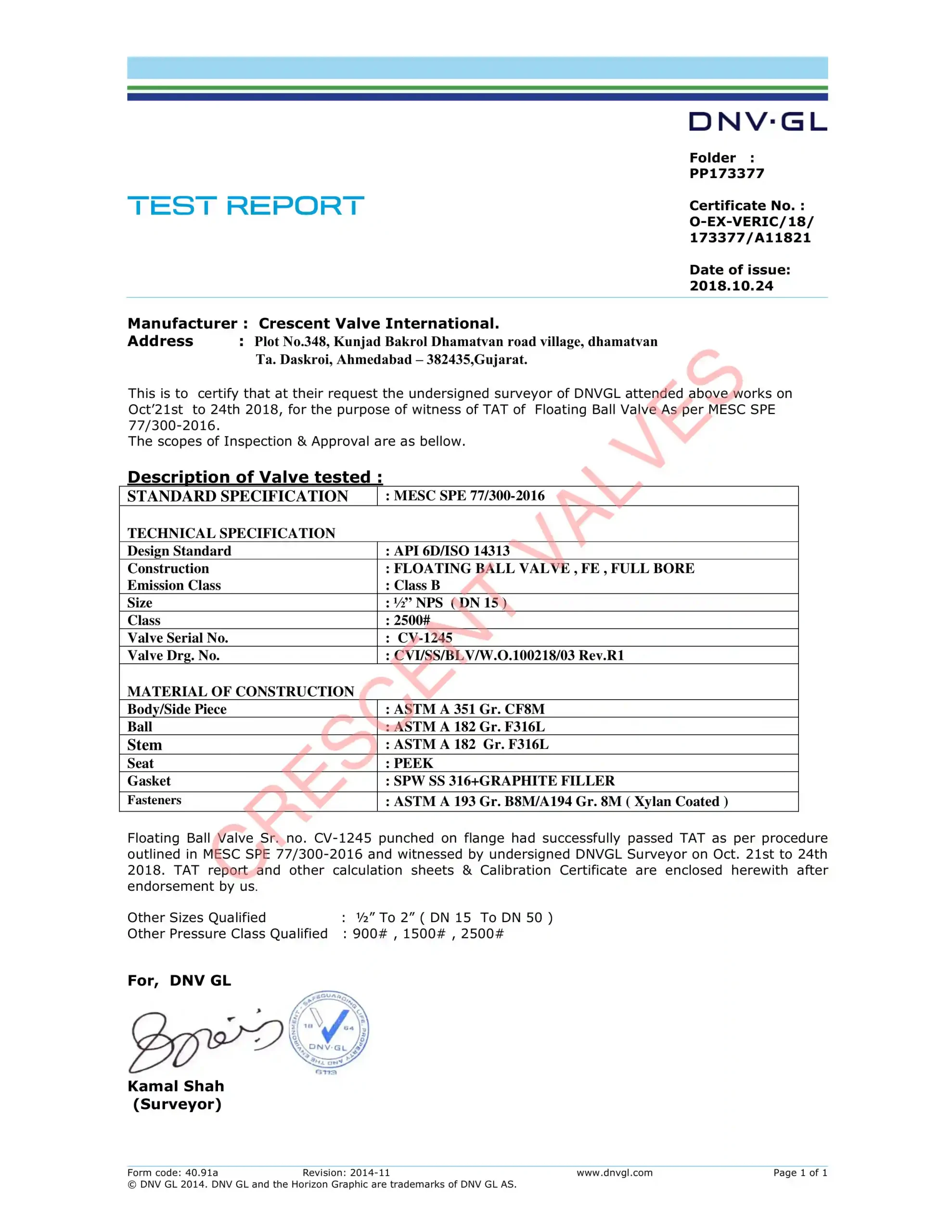

Product Description

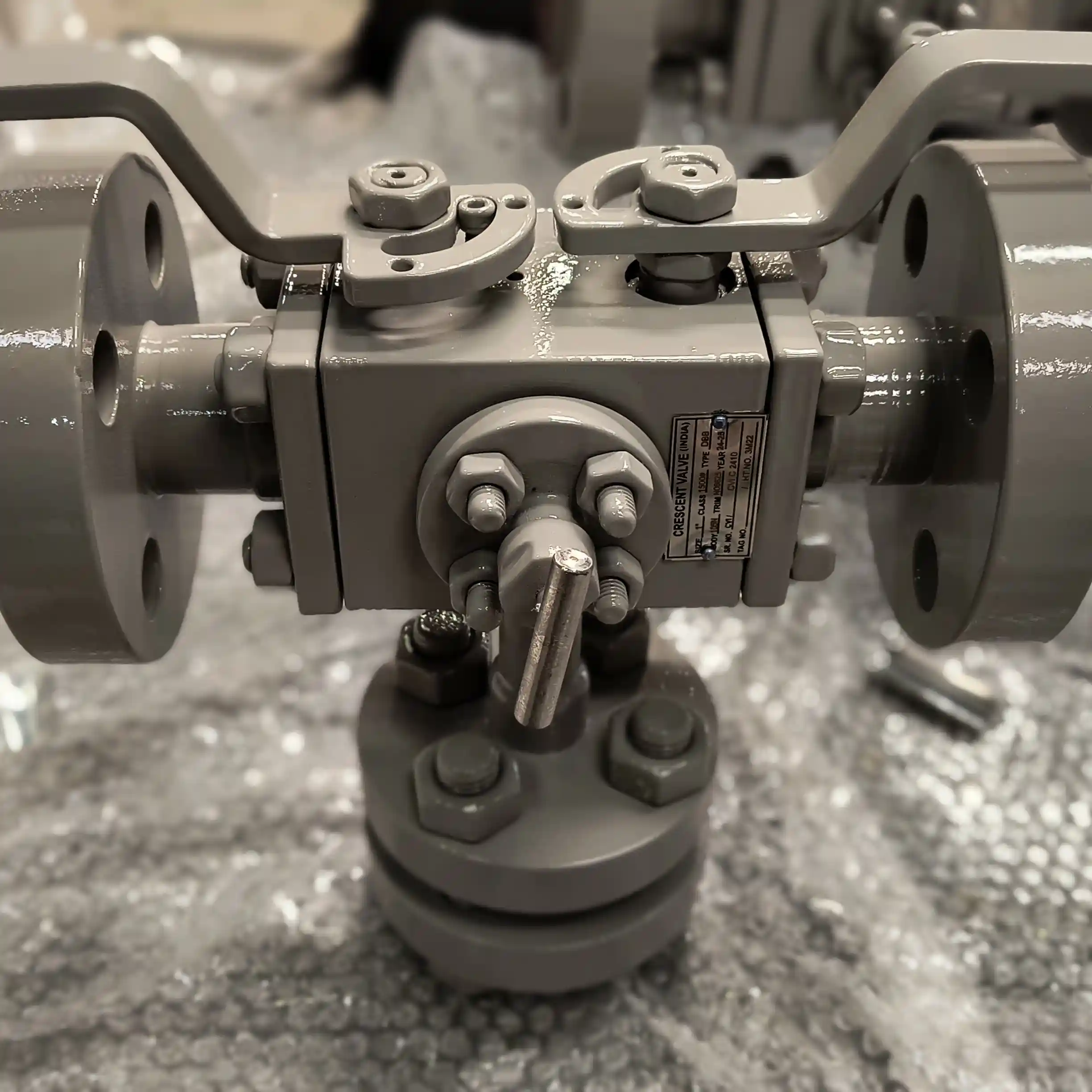

Crescent Valves manufactures a comprehensive range of Floating Type Double Block and Bleed (DBB) Ball Valves in sizes up to 4″ (DN 100) and Pressure Rating from 150# to 2500#, engineered to deliver superior isolation, safety, and performance across various process industries.

These valves are offered in multiple combinations of size, pressure class, material of construction, and end connections to meet the specific needs of oil & gas, petrochemical, power, and chemical processing applications.

Crescent Floating Design DBB Valves are designed primarily for downstream applications, featuring two precision-engineered ball rings that securely position the ball under varying pressure conditions. This ensures reliable sealing performance and consistent operation across a wide range of pressures and temperatures.

The Double Block and Bleed configuration provides positive isolation on both upstream and downstream sides, while the bleed port enables safe cavity venting, pressure relief, or monitoring.

Valves are available in Ball–Needle–Ball configurations, as well as single flanged, double flanged, and manifold-type designs, with options for both soft-seated and metal-to-metal sealing to suit different service conditions.

Specification

- Size: 1/2″ to 4″ (DN 15 to DN 100)

- Rating: ASME CL 150 to 2500

- Design: ASME B 16.34 / ISO 17292 / API 608 / API 6D

- Face to Face: As per Mfg.

- End Connection: ASME B 16.5 / ASME B 16.25 / ASME B16.11 / ASME B 1.20.1

- Testing: API 598 / API 6D / ISO 5208

- Fugitive Emission: ISO 15848 Part 1 & 2 / MESC SPE 77/312

- Fire Safe: API 607 / API 6FA

- Special: NACE MR 0175

- Material: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconnel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Features

- Compact Design

- Fire Safe Design

- Blowout-proof stem

- High integrity stem sealing

- Mirror-finished solid ball

- Antistatic feature

- Low Emission

- Soft & Metal Seated

- Extended Stem Desgin for Cryogenic Service

- Actuator-mounting flange conforms to ISO 5211

- Variety of actuation options

Technical Data

| PART NAME | DESCRIPTION |

|---|---|

| Body | ASTM A105 / ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| Side PC / Adapter | ASTM A105 / ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| Ball | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze / Alloy 20 / Titanium |

| Seat Insert | PTFE / R-PTFE / PEEK / NYLON / DEVLON / DELRIN |

| Seat Ring | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Stem | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Bolting | A193 B7 / A320 L7 / A193 B8/ Alloy / Inconel 925 |

| Bolting | A194 2H / A194 8 / Alloy / Inconel 925 |

* For more details download our Catalogue and any other material contact the factory