Product Description

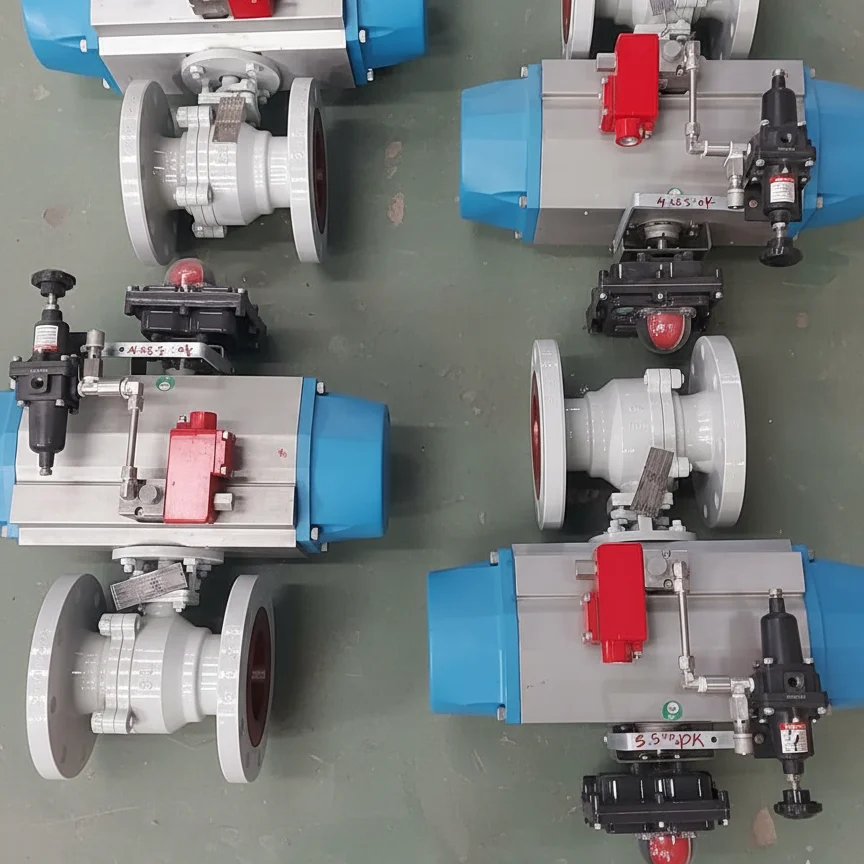

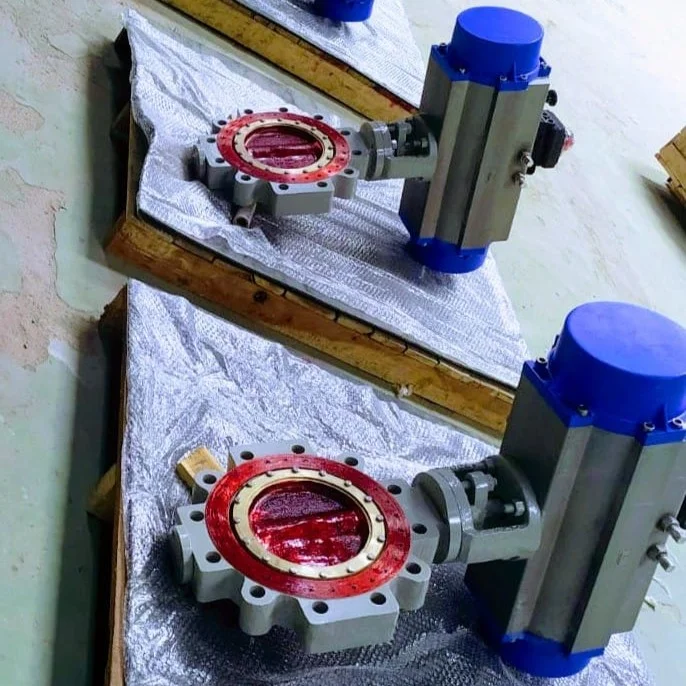

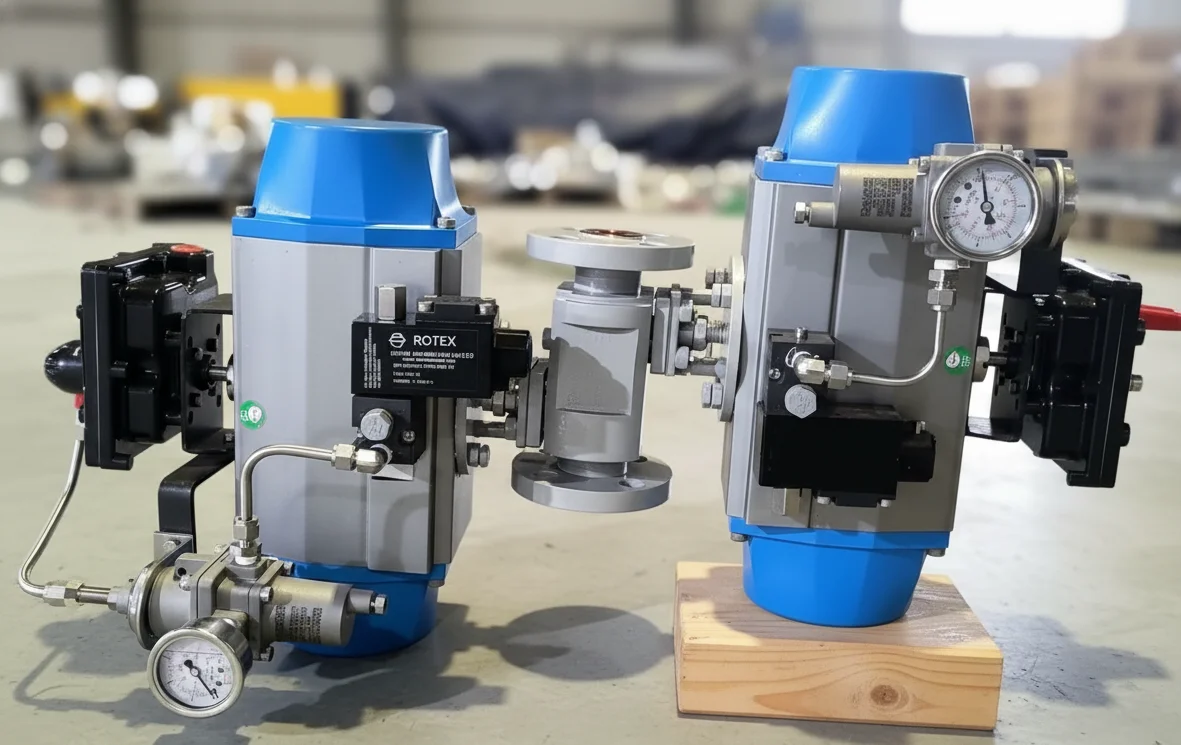

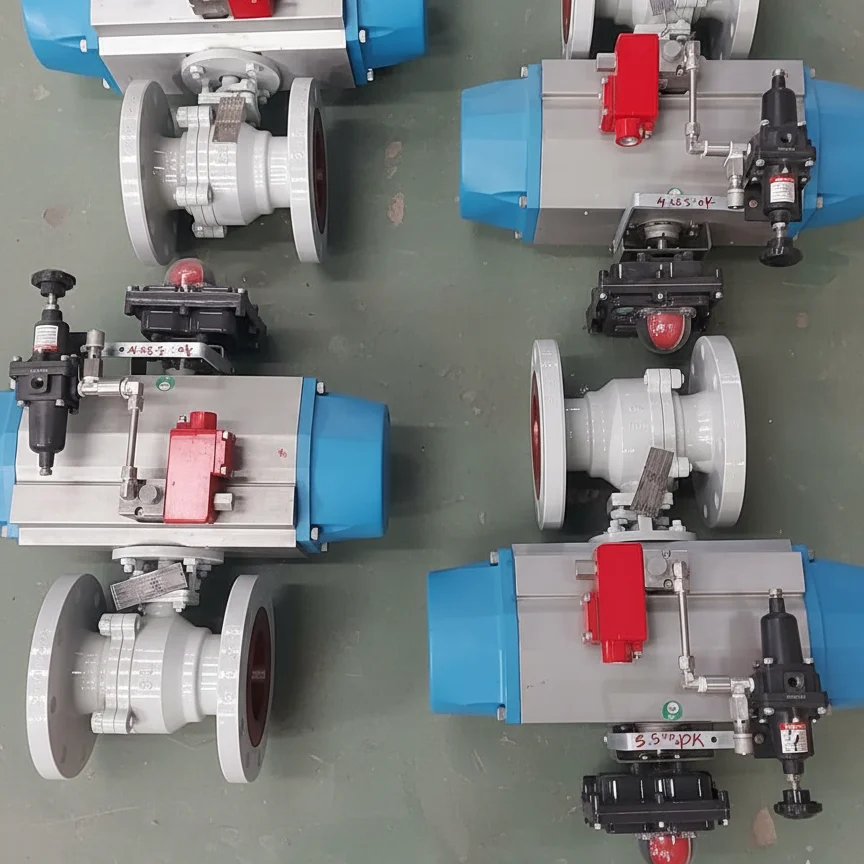

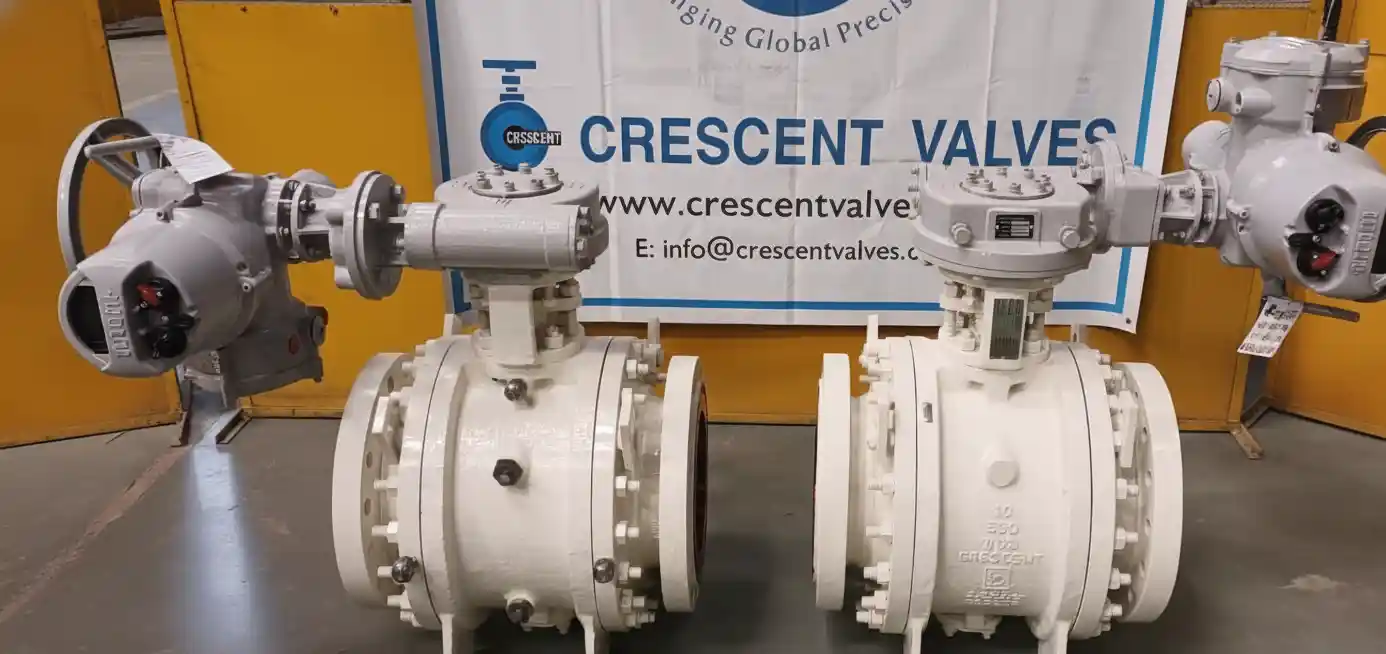

Crescent Valves manufactures a comprehensive range of Emergency Shutdown (ESD) Valves in Size up to 40″ and Pressure Rating 150# to 2500#, ESD Valves designed to provide rapid, reliable, and fail-safe isolation in critical process applications across oil & gas, petrochemical, chemical, and power industries.

ESD valves are engineered to quickly shut off flow in emergency situations, protecting personnel, equipment, and the environment. They are available in various materials of construction and end connections to meet the specific requirements of high-risk and high-pressure systems.

Crescent ESD Valves can be supplied in Ball, Butterfly, and Gate configurations, and are compatible with pneumatic, hydraulic, or electric actuators for fast and precise operation. These valves are designed for integration with Safety Instrumented Systems (SIS) and comply with international safety standards such as IEC 61508 / IEC 61511.

The valves feature robust construction, tight sealing, and high-cycle durability, ensuring reliable operation under extreme pressures, temperatures, and corrosive environments. Optional features include fail-safe operation, manual override, position feedback, and SIL certification for safety-critical applications.

Crescent ESD Valves combine safety, reliability, and precision, ensuring rapid flow isolation in emergency conditions, while maintaining long-term operational integrity and compliance with international safety standards.

Specification

- Size: Up to 40″ (DN 1000)

- Rating: ASME Class 150 to 2500

- Design: ASME B 16.34 / ISO 17292 / API 608 / API 6D/ API 609 AND ETC.

- Face to Face: ASME B16.10 /API 609

- End Connection: ASME B 16.5 / ASME B 16.25 / ASME B16.11 / ASME B1.20.1 (Flanged, Welded, Threaded as per project)

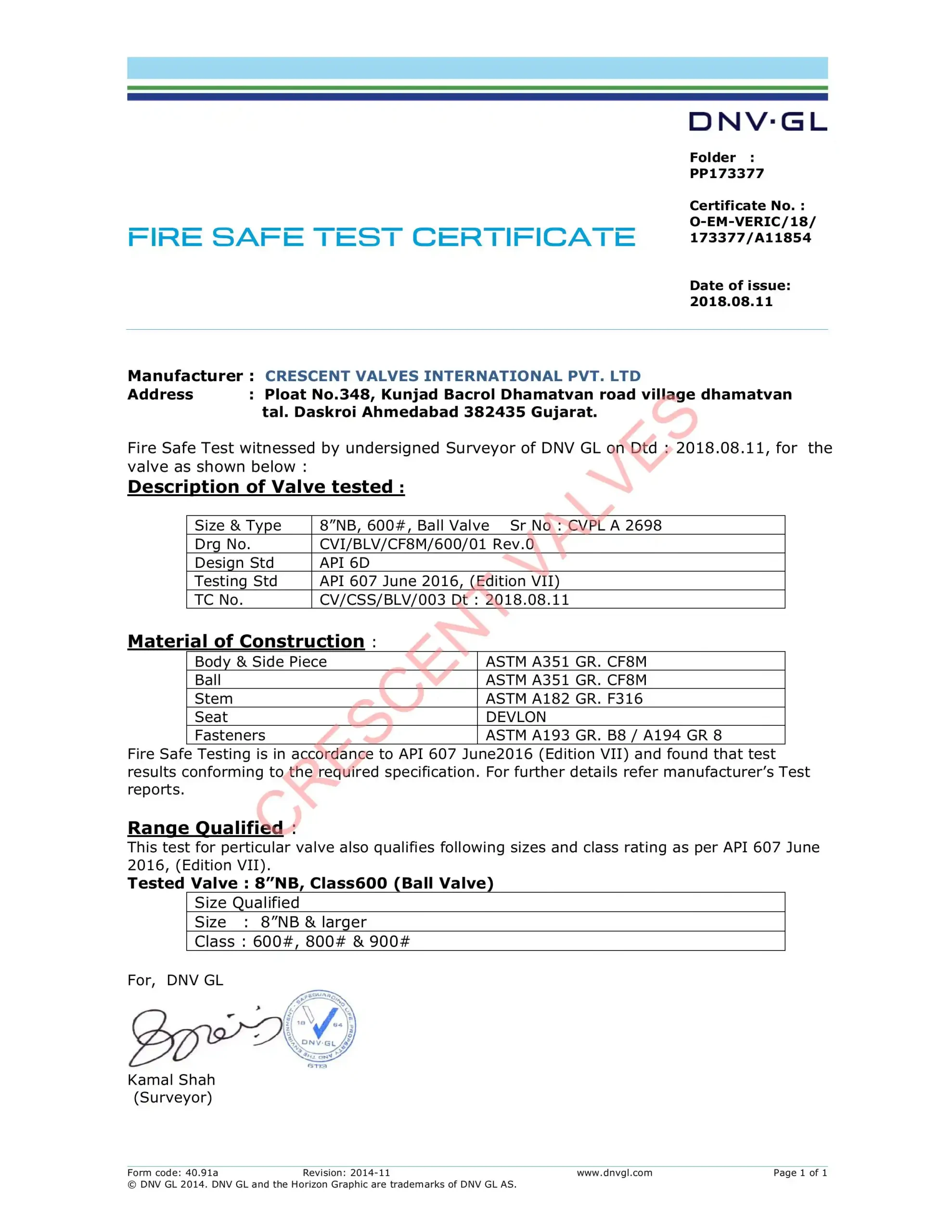

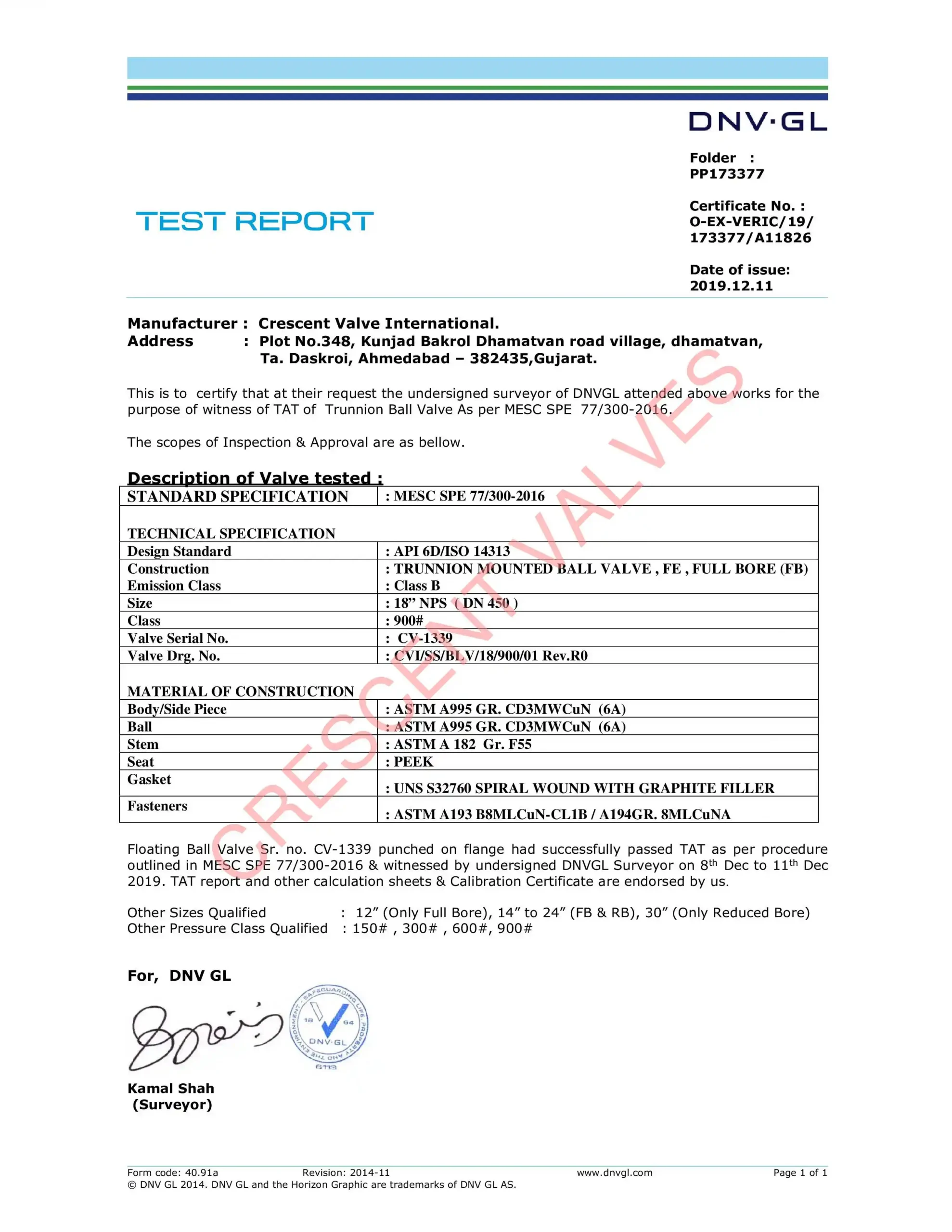

- Testing: API 598 / API 6D / ISO 5208 / BS EN 12266-1

- Fugitive Emission: ISO 15848 Part 1 & 2 / MESC SPE 77/312

- Fire Safe: API 607 / API 6FA

- Special: NACE MR 0175

- Material: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex & Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconel, Titanium Alloy, Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

- Valve Types: Emergency Shut Down Valves (ESDV), Shut Down Valves (SDV), On/Off Valves, Motor Operated Valves (MOV)

- Applications: Oil & Gas, Petrochemical, Refinery, Power, Process Plants, General Industries

Features

- Compact & robust design for automated operation

- Fire Safe Design

- Blowout-proof stem

- High integrity stem sealing

- Mirror-finished solid closure element (Disc/Ball/Gate depending on type)

- Antistatic feature

- Low Emission / Fugitive Emission Compliance

- Soft & Metal Seated Options

- Extended Stem Design for Cryogenic & High-Temperature Services

- Actuator-mounting flange conforms to ISO 5211

- Variety of actuation options (Pneumatic, Hydraulic, Electric)

- Seamless integration with actuators & accessories for precise automation

- Ensures reliable and consistent operation under demanding conditions

- Optimized execution schedules for improved project delivery and customer satisfaction

Technical Data

| PART NAME | DESCRIPTION |

|---|---|

| Body | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| Side PC / Adapter | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800 / Alloy 20 / Titanium |

| Ball | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze / Alloy 20 / Titanium |

| Seat Insert | PTFE / R-PTFE / PEEK / NYLON / DEVLON / DELRIN |

| Seat Ring | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Seat Spring | Inconel X-750 / 718 |

| Stem | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| O Ring | Viton / HNBR |

| Trunnion Cover | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| Trunnion | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze / Alloy 20 / Titanium |

| Bolting | A193 B7 / A320 L7 / A193 B8/ Alloy / Inconel 925 |

| Bolting | A194 2H / A194 8 / Alloy / Inconel 925 |

Product Description

Crescent Valves designs and manufactures a comprehensive range of Motor Operated Valves (MOVs) in sizes up to 40″ and pressure ratings 150# to 2500#, suitable for automated flow control in oil & gas, petrochemical, power, water, and process industries.

These valves are equipped with high-performance electric actuators for reliable remote operation, enabling precise control, regulation, and shut-off in critical applications. MOVs are available in multiple configurations, including Gate, Globe, Ball, and Butterfly valves, offering flexibility across a wide range of process requirements.

Each valve-actuator assembly is engineered for accuracy, durability, and fail-safe operation, ensuring dependable performance under demanding service conditions. The actuators can be supplied with manual override, limit switches, torque control, and position indicators to suit specific automation and control needs.

MOVs can be configured for on/off or modulating control, integrated with SCADA, PLC, or DCS systems for complete process automation. Crescent’s MOVs are designed to comply with relevant international standards and can be tailored to meet customer specifications for torque, voltage, and enclosure protection (IP/Ex rated).

Crescent Motor Operated Valves offer a perfect blend of automation, reliability, and safety, ensuring efficient flow control and seamless integration into modern industrial systems.

Specification

- Size: Up to 40″ (DN 1000)

- Rating: ASME Class 150 to 2500

- Design: ASME B 16.34 / ISO 17292 / API 608 / API 6D/ API 609 AND ETC.

- Face to Face: ASME B16.10 /API 609

- End Connection: ASME B 16.5 / ASME B 16.25 / ASME B16.11 / ASME B1.20.1 (Flanged, Welded, Threaded as per project)

- Testing: API 598 / API 6D / ISO 5208 / BS EN 12266-1

- Fugitive Emission: ISO 15848 Part 1 & 2 / MESC SPE 77/312

- Fire Safe: API 607 / API 6FA

- Special: NACE MR 0175

- Material: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex & Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconel, Titanium Alloy, Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

- Valve Types: Emergency Shut Down Valves (ESDV), Shut Down Valves (SDV), On/Off Valves, Motor Operated Valves (MOV)

- Applications: Oil & Gas, Petrochemical, Refinery, Power, Process Plants, General Industries

Features

- Compact & robust design for automated operation

- Fire Safe Design

- Blowout-proof stem

- High integrity stem sealing

- Mirror-finished solid closure element (Disc/Ball/Gate depending on type)

- Antistatic feature

- Low Emission / Fugitive Emission Compliance

- Soft & Metal Seated Options

- Extended Stem Design for Cryogenic & High-Temperature Services

- Actuator-mounting flange conforms to ISO 5211

- Variety of actuation options (Pneumatic, Hydraulic, Electric)

- Seamless integration with actuators & accessories for precise automation

- Ensures reliable and consistent operation under demanding conditions

- Optimized execution schedules for improved project delivery and customer satisfaction

Technical Data

| PART NAME | DESCRIPTION |

|---|---|

| Body | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| Side PC / Adapter | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800 / Alloy 20 / Titanium |

| Ball | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze / Alloy 20 / Titanium |

| Seat Insert | PTFE / R-PTFE / PEEK / NYLON / DEVLON / DELRIN |

| Seat Ring | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Seat Spring | Inconel X-750 / 718 |

| Stem | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| O Ring | Viton / HNBR |

| Trunnion Cover | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| Trunnion | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze / Alloy 20 / Titanium |

| Bolting | A193 B7 / A320 L7 / A193 B8/ Alloy / Inconel 925 |

| Bolting | A194 2H / A194 8 / Alloy / Inconel 925 |