Product Description

Crescent Valves manufactures a comprehensive range of Swing Type Check Valves in sizes from 2″ to 40″ (DN 50 to DN 1000) and pressure ratings from 150# to 2500#, designed to ensure unidirectional flow and prevent backflow in various process applications.

These valves are available in multiple combinations of size, pressure class, materials of construction, and end connections to suit diverse industrial requirements.

Crescent Swing Check Valves feature a one-piece disc construction, securely fastened to the hinge by a lock nut and pin, allowing the disc to rotate freely to minimize localized wear. The hinge pin is designed for excellent wear resistance, ensuring long-term reliability.

The valves are offered in Standard Bolted Bonnet as well as Pressure Seal designs to accommodate high-pressure and high-temperature applications, providing tight sealing and robust performance.

Crescent Swing Check Valves deliver durable, reliable, and low-maintenance performance, ensuring efficient backflow prevention in critical industrial systems.

Specification

- Size: 2″ to 40″ (DN 15 to DN 1000)

- Rating: ASME CL 150 to 2500

- Design: API 6D / API 594 / ISO 1868 /ASME B 16.34

- Face to Face: ASME B 16.10

- End Connection: ASME B 16.5 / ASME B 16.25

- Testing: API 598 /API 6D / BS EN 12266-1

- Fugitive Emission: ISO 15848 Part 1 & 2

- Fire Safe: API 607 / API 6FA

- Special: NACE MR 0175

- Material: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconnel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Features

- Bolted Cover Design

- Swing Type Disc

- One Direction & Automatically Prevents Backflow

- Metal-to-Metal Sealing

- Low Pressure Drop

- Automatic Operation

- By-pass on Request

- Horizontal or vertical installation compatibility

Technical Data

| PART NAME | DESCRIPTION |

|---|---|

| Body | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800 / Titanium |

| DISC | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800 / Titanium |

| HINGE | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| SEAT RING | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| DISC PIN & NUT | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| HINGE PIN | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Bolting | A193 B7 / A320 L7 / A193 B8/ Alloy / Inconel 925 |

| Bolting | A194 2H / A194 8 / Alloy / Inconel 925 |

* For more details download our Catalogue and any other material contact the factory

Product Description

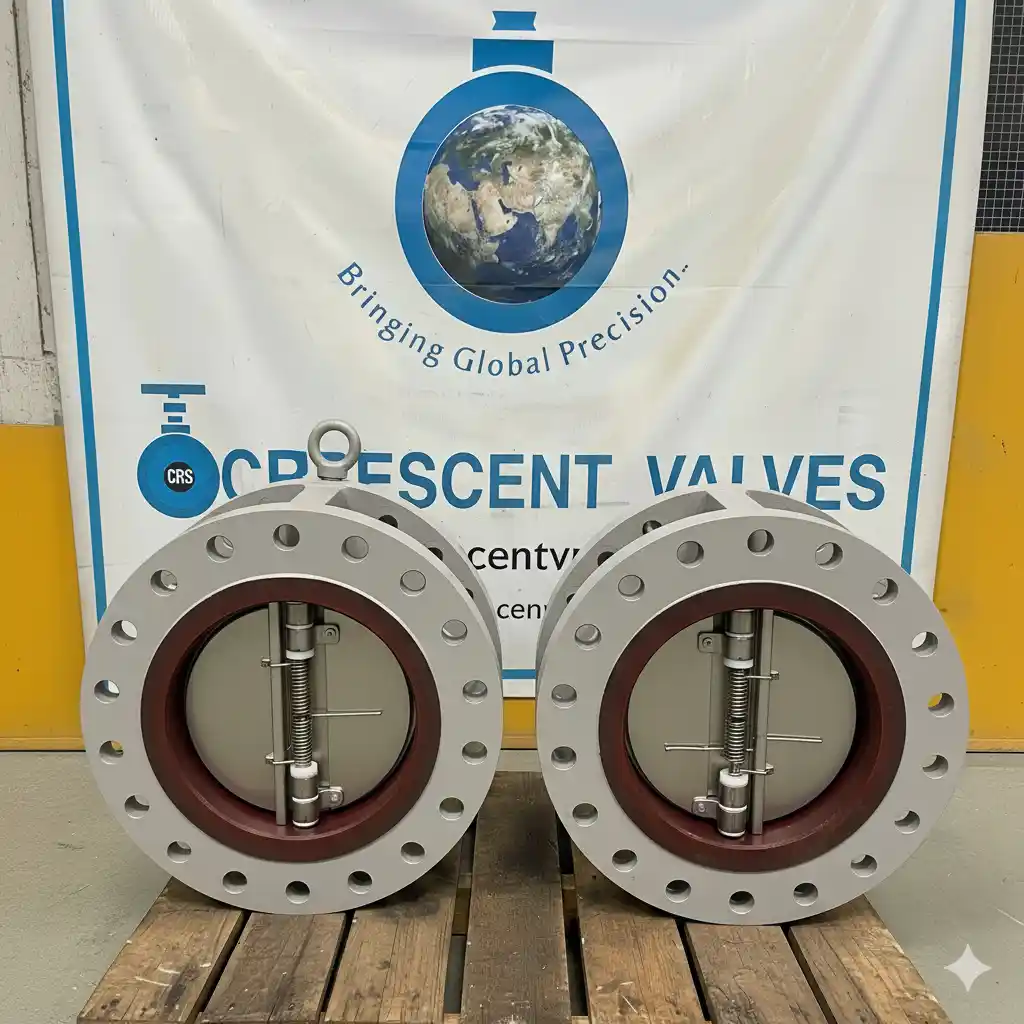

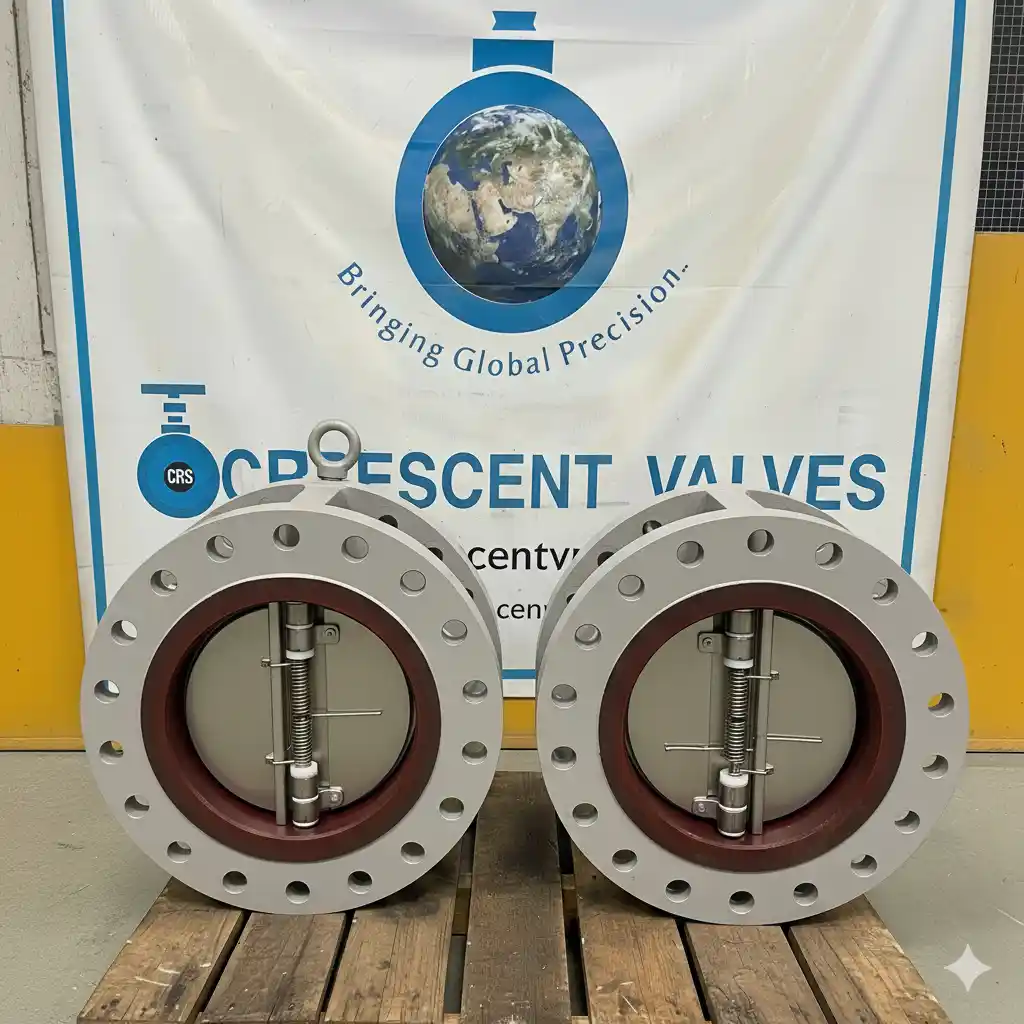

Crescent Valves manufactures a comprehensive range of Dual Plate Check Valves in sizes from 2″ to 24″ (DN 50 to DN 600) and pressure ratings from 150# to 1500#, designed to ensure unidirectional flow and prevent backflow in various process applications.

These valves are available in multiple combinations of size, pressure class, materials of construction, and end connections to meet the requirements of diverse industrial environments.

Crescent Dual Plate Check Valves feature two spring-loaded plates mounted on a central hinge, providing quick closure to prevent reverse flow. This design ensures minimal pressure drop, reduces water hammer, and delivers reliable operation in demanding conditions.

Constructed from a wide range of durable materials, these valves are suitable for high-cycle, high-pressure, and corrosive service applications. Their compact design allows for easy installation and maintenance, making them ideal for oil and gas, chemical, power, and petrochemical industries.

Specification

- Size: 2″ to 24″ (DN 2 to DN24)

- Rating: ASME CL 150 to 1500

- Design: API 594 & API 6D

- Face to Face: API 594 & API 6D

- End Connection: Wafer & Lug Suitable To Flanged ASME B 16.5 & Double Flange

- Testing: API 598 / API 594

- Fugitive Emission: ISO 15848 Part 1 & 2

- Fire Safe: API 607 / API 6FA

- Special: NACE MR 0175

- Material: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconnel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Features

- Retainerless body Design

- Available in Wafer, Lug and Double Flange styles

- Compact Design

- Quick Closure

- Low Pressure Drop

- Versatility installation

- Smooth finish and superior sealing

Technical Data

| PART NAME | DESCRIPTION |

|---|---|

| Body | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| Disc | ASTM A216 GR WCB / ASTM A352 GR LCB / ASTM A351 CF8M / ASTM A995 GR 6A / ASTM A494 CW6MC / ASTM A351 CK3MCUN / ASTM B148 C95800/ Alloy 20 / Titanium |

| Seat (Metal & Soft) | Stellite Hard Faced / SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze / Alloy 20 / Titanium / RPTFE / PTFE/ EPDM / VITON |

| Spring | Inconel X-750 / Inconel 718 / SS 316 |

| Hinge | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

* For more details download our Catalogue and any other material contact the factory

Product Description

Crescent Valves manufactures a comprehensive range of Spring-Loaded Piston Check Valves in sizes from 1/2″ to 2″ (DN 15 to DN 50) and pressure ratings from 150# to 2500#, designed to ensure unidirectional flow and prevent backflow in high-pressure and high-temperature applications.

These valves are engineered for rapid response and reliable shut-off, making them ideal for steam, oil, gas, chemical, and petrochemical industries. They are available in various combinations of size, pressure class, materials of construction, and end connections to meet a wide range of plant and process requirements.

Crescent Spring-Loaded Piston Check Valves feature a spring-loaded disc, which ensures automatic closure when flow reverses, providing tight sealing, reduced water hammer, and smooth operation. This design ensures minimal pressure drop and long-term reliability even in high-pressure, high-temperature, or corrosive environments.

Specification

- Size: 1/2″ to 2″ (DN 15 to DN 50)

- Rating: ASME CL 150 to 2500

- Design: API 602 /BS 5352 / ASME B 16.34

- Face to Face: As per Mfg (SW/THD) / ASME B 16.10 (Flange)

- End Connection: ASME B 16.11 / ASME B 2.1 / ASME B16.5

- Testing: API 598 / BS EN 12266-1 Part 1

- Fugitive Emission: ISO 15848 Part 1 & 2

- Fire Safe: API 607 / API 6FA

- Special: NACE MR 0175

- Material: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconnel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Features

- Bolted Cover Design

- Guided Piston Type Disc

- Flow in One Direction & Automatically Prevents Backflow

- Metal-to-Metal Sealing for Leak-tight Performance

- Low Pressure Drop

- Automatic Operation

- Suitable for Horizontal or Vertical Installation

Technical Data

| PART NAME | DESCRIPTION |

|---|---|

| Body | ASTM A105 / SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Seat Ring | SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Disc | ASTM A105 / SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Cover | ASTM A105 / SS316 / Duplex / Inconel 625 / Inconel 825 / Al Bronze/ Alloy 20 / Titanium |

| Spring | Inconel X-750 / Inconel 718 / SS 316 |

| Bolting | A193 B7 / A320 L7 / A193 B8/ Alloy / Inconel 925 |

| Bolting | A194 2H / A194 8 / Alloy / Inconel 925 |

* For more details download our Catalogue and any other material contact the factory